160KW Industrial IGBT Induction Heating Hardening Machines (GYS-160AB)

Main characteristics

1.Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2. 100% Duty cycle, continuous working is allowed at maximum power output.

3.Display of heating power and heating current and oscillating frequency;

4. Simple to install, Installation can be done by unprofessional person very easily;

5. Light weight

6.Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

7.Constant current or constant power status can be selected accordingly to achieve higher heating efficiency;

Advantage

Nearly 20 years experience, stable and goods performance

CE,SGC,FCC,ROSH certificated

Cooperated with GM,VOLVO,HONDA and so on.

Suitable for a large range, heating, quenching, forging, melting, soldering and so on.

Less environment pollution

High efficiency,high output&high reliability

Small size &light weight

Parameter:

Delivery Time: within 7 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

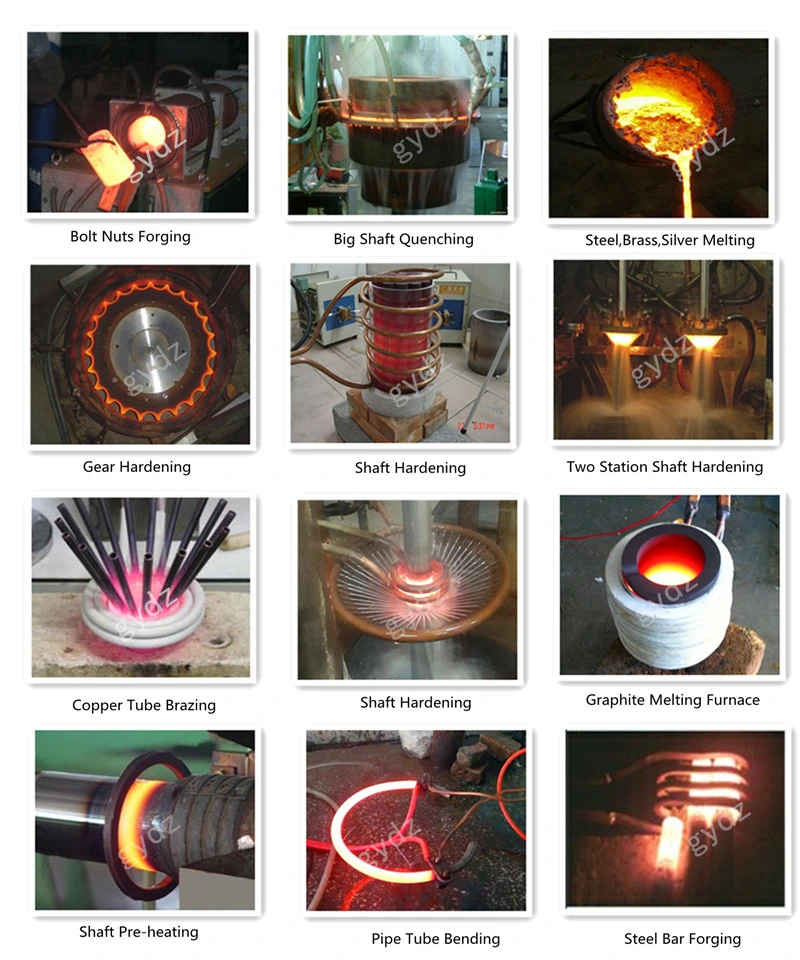

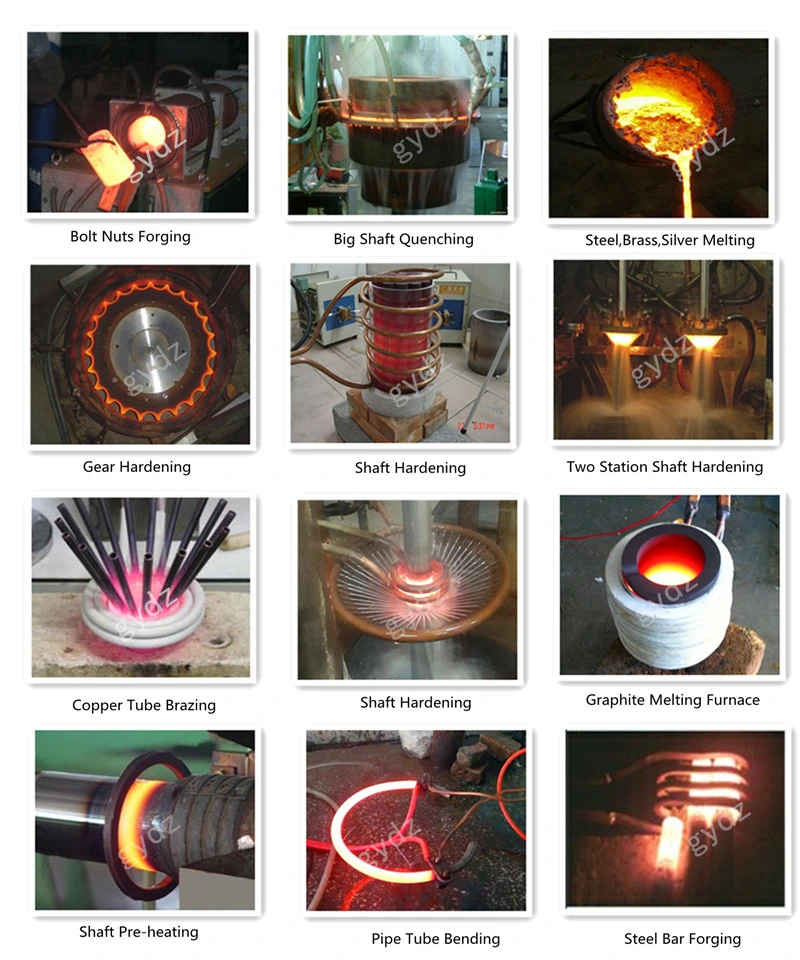

Machine Application Photo

Main characteristics

1.Siemens IGBT module and Inverting technologies of third generation been used; Higher reliability and lower maintenance cost.

2. 100% Duty cycle, continuous working is allowed at maximum power output.

3.Display of heating power and heating current and oscillating frequency;

4. Simple to install, Installation can be done by unprofessional person very easily;

5. Light weight

6.Advantages of the model with timer: The power and the operating time of the heating period and the retain period can be preset respectively, to realize a simple heating curve, this model is suggested to use for batch production to improve the repeatability;

7.Constant current or constant power status can be selected accordingly to achieve higher heating efficiency;

Advantage

Nearly 20 years experience, stable and goods performance

CE,SGC,FCC,ROSH certificated

Cooperated with GM,VOLVO,HONDA and so on.

Suitable for a large range, heating, quenching, forging, melting, soldering and so on.

Less environment pollution

High efficiency,high output&high reliability

Small size &light weight

Parameter:

| Model | GYS-160AB (Three phase) |

| Work power | 340V-430V |

| Maximum input current | 240A |

| Output power | 160KW |

| Fluctuating frequency | 10-50KHZ |

| Output current | 400-6500A |

| The flow rate of cooling water | 0.08-0.16Mpa 15L/Min |

| Water temperature protection point | 50C |

| Product size | main : 870x695x1050mm |

| transformer : 850x420x750mm | |

| Net weight | main : 135kgs |

| transformer : 85kgs |

Shipping Term:By sea,By air,by express.

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Machine Application Photo